COMMON MISTAKES IN DIMENSIONAL CALIBRATION METHODS

An educational presentation from the leading manufacturer of metrology instruments

Mitutoyo Institute of Metrology

The Mitutoyo Institute of Metrology provides educational courses and on-demand resources across a wide variety of measurement related topics including basic

inspection techniques, principles of dimensional metrology, calibration methods, and GD&T. Visit www.mitutoyo.com/education for details on the educational

opportunities available from Mitutoyo America Corporation.

About this Presentation

Mitutoyo America Corporation has a long history of providing world-class calibration services as well as premier educational instruction in calibration methods and techniques. This presentation is based on some of the key issues that have been observed in our popular Hands-On Gage Calibration course over the years. Calibration is all about maintaining quality and establishing traceability for measuring equipment. To achieve these goals, calibration must be a well-engineered search for errors. Economic realities limit the amount of time and testing in calibration, and therefore methods must be chosen wisely to provide the most information with the least amount of work. This presentation leverages the excellent American national standards available in dimensional metrology – the B89 series of standards developed under the auspices of the American Society of Mechanical Engineers (www.asme.org). This presentation has been delivered by Mitutoyo America personnel at a number of conferences and other events, in particular at national and regional NCSL International meetings (www.ncsli.org).

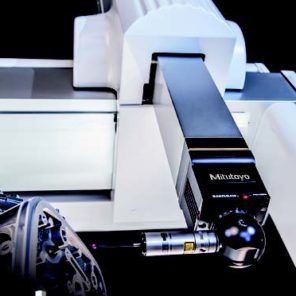

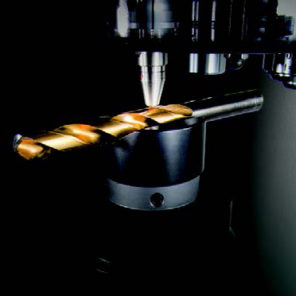

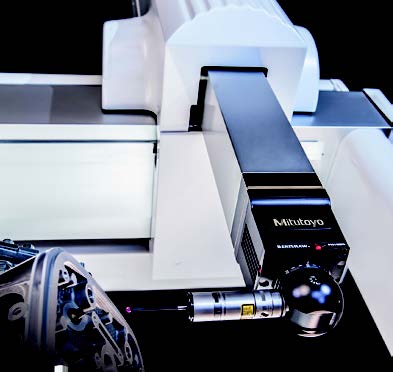

Coordinate Measuring Machines

Sensor Systems

Vision Measuring Systems

Test Equipment and Seismometers

Coordinate Measuring Machines

Sensor Systems

Coordinate Measuring Machines

Sensor Systems

Coordinate Measuring Machines

Sensor Systems