The automotive industry is one of the greatest users of statistical process control. Whether an OEM, Tier1, Tier2 or other supplier of automotive components, manufacturers are constantly striving for consistent product quality and improved profitability. Reducing process variation, monitoring critical characteristics, realizing continuous improvement and reducing administrative workloads are just a few of the techniques used to meet these goals.

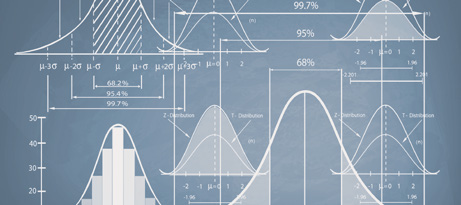

Reduce Process Variation

Reducing process variation and increasing process stability is essential to improving product quality. Stable processes produce less scrap and require less inspection which saves time and money. MeasurLink® is the perfect tool for these ongoing activities.

- Monitor real time capability indices

- Use pre-control charting to reveal variation and mean shifts in data

- Compare multiple operations performing the same processes to increase overall quality

- Use historical data to predict tool life to reduce defects due to breakage

Monitoring Critical Characteristics

Automotive manufacturers constantly monitor critical characteristics to ensure the quality their customers demand and reduce the risk of product recalls. Recalls are not only costly but can permanently damage the reputation of a company and their OEM customers.

MeasurLink® can be used to:

- Provide visibility to these characteristics

- Monitor capability indices in real-time

- Perform data tests as each subgroup is measured

- Alert operators and engineers the instant a defective part is

measured through email alerts

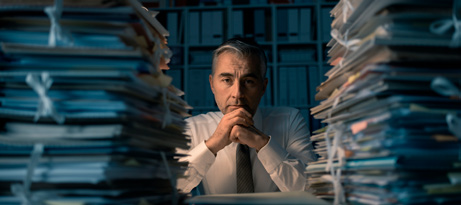

Process improvement is very important in automotive manufacturing. Mass production allows manufacturers to refine their process to be more cost effective while reducing the risk of non-conformities. Going paperless is also a large initiative taken by many facilities. MeasurLink® is a great tool for both of these activities. Electronic Data collection and database retention allows for reduced record keeping and instant access to data.

Continuous Improvement

Continuous Improvement activity is nonstop in automotive facilities locally and globally. Constantly improving your process will not only improve the quality of your products, it will also save you money. By having more efficient processes, customer satisfaction will also improve.

Use MeasurLink® to:

- Reduce scrap

- Prevent non-conformities

- Reduce cycle time

- Improve tool life accuracy

Reduce the Workload

Reduce the workload associated with managing inspection data. MeasurLink® Real-Time eliminates the need for paper based data collection. Electronic data collection not only enables faster, more accurate data collection, but it also makes reporting, data mining and audit preparation a simpler task.

- Faster inspection times

- More accurate data collection

- Reduced dependency on spreadsheets

- Gather data from electronic gages, RS232 devices, PC based metrology equipment, PLC’s and more